Content

- How To Calculate Reorder Point?

- What Is The Reorder Formula?

- Reorder Point Formula

- Inventory Reorder Point Excel Template

- In This Amazon Reorder Point Guide, Well Take A Look At:

- Why Is Direct To Consumer Customer Retention Important In Ecommerce?

- How To Calculate Reorder Point

- How To Calculate Reorder Point Formula?

Some say “healthy eating begins in the grocery store.” Similarly, the efficiency of an eCommerce operation begins in the reordering and purchasing phase. The definition of reorder point is the point at which you send a purchase order to your supplier or manufacturer. Point-of-sale systems will alert you that the item is low on stock, and automatically fill a purchase order form for that item.

It is a minimum amount of an item which a firm holds in stock, such that, when stock falls to this amount, the item must be reordered. It is normally calculated as the forecast usage during the replenishment lead time plus safety stock. In the EOQ model, it was assumed that there is no time lag between ordering and procuring of materials. To calculate lead time demand for your business, calculate the average number of product sales your business experiences daily.

How To Calculate Reorder Point?

Material Requirements Planning Production planning, capacity planning, raw material purchase scheduling. Job Costing Accurately track your business’ job costing and identify trends and opportunities with the highest profit potential. Reorder point is not a stable number, but is flexible based on sales trends and the demand cycle of a given product.

Demand planning and forecasting is key to the future of your manufacturing business. It’s important to know how much you’re going to need be stocking up on. So, although having an effective reorder point policy means you have freed up more time in your week, you still need to stay on top of things by making new reorder point calculations. Now you know how and when to order new materials to avoid stockouts. However, the real question is how much material do you have to order to keep your productions running smoothly.

What Is The Reorder Formula?

You might have a single item that sells consistently, requiring you to keep it stocked often and at higher numbers than other products. For example, Apple’s iPhone is far more popular than any other product they produce, so its daily sales velocity is likely higher than their laptops or iPads. The reorder point varies from product to product and is primarily influenced by two critical factors – daily sales velocity and lead time. You can set reorder points for specific products, but reordering would only trigger when you drop below a company-wide stock level of X .

It also means more cash tied up in the cost of the inventory itself, making your finances less liquid. Finally, some inventory will depreciate in value over time, be it perishable foods or trendy clothing. For instance, fashion retailers need to solve the ROP formula separately for every color and every size of every item. The end result will produce an inventory quantity that will indicate when it’s time to order more. If you wait to order until you have run out of inventory, then there will be a lag between when you place the order and when you can sell your new inventory. Setting a reorder point can help you reorder in time to avoid this availability gap. No matter what your category, if you have products you can’t sell, you either have to keep paying to store them, or you need to dispose of them, which also comes with a cost.

Reorder point is an important metric that tells you the optimal amount of stock to order and when. With a simple formula, you can calculate your reorder point and use that data to enhance your stock replenishment system. This method also takes the guesswork out of your forecast data too, so you’ll have a more accurate prediction in the future. This means you can better plan for potential demand spikes and stockouts, as well as keep storage costs low and your bottom line happy.

Reorder Point Formula

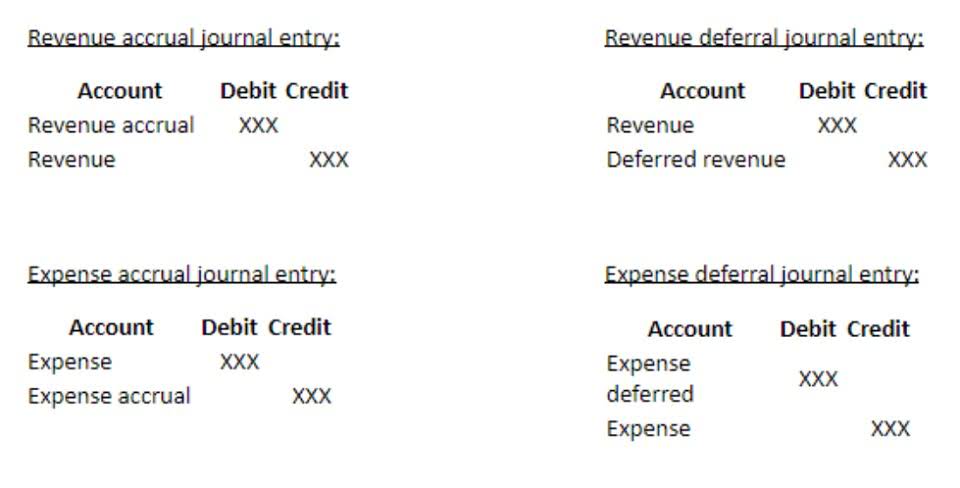

First, find the difference between the expected lead time and the actual lead time and place this in the deviance column. Businesses using reorder point calculator spreadsheets can find their reorder points in Excel by using the formula above in the spreadsheet holding their inventory data. Each point-of-sale, or POS, system uses reorder points in a different way. For example, some will calculate reorder points for you automatically, while others use the reorder points you enter to help automate the reordering process.

- This includes sending you “Targeted Messages on 3rd Party Advertising Platforms” as described in the Privacy Notice.

- When your inventory falls to that quantity, it’s time to order more.

- Due to unexpected seasonal demand, Exempli’s supplier was also running low on product, adding an additional 2 days to get stock in from their manufacturer.

- While you may choose to use an approximation of the lead times by using the supplier’s contracted lead time, I do recommend studying your lead time variation at least once a year.

- Unforeseen events such as shortages, broken equipment, inclement weather, and road work can cause variances in delivery time.

- Inventory management software, you have an option to specify the reorder point for certain items, so that the system can issue reminders when you reach this stock point.

- If a business reorders too much, too soon, it will be spending money before it needs to, while also incurring costs to carry the extra inventory, some of which may never be sold .

Warehousing a lot of merchandise over long periods can quickly cut into profit margins. If the product has a short shelf life – like food – and it goes bad or expires before it’s purchased, then you’ve paid money to a supplier and won’t make it back.

Inventory Reorder Point Excel Template

Using this formula to manage your inventory can help minimize costs and stockouts and provide better demand forecasting as your business grows. To calculate your https://www.bookstime.com/, you simply need to multiply the average unit sales by average lead time and include your safety stock levels. Next, let’s look into how to calculate your reorder point with the reorder point formula. This doesn’t have to be done by hand, you can getcloud-based softwareto do it for you, and let you know when you’re running low. The reorder point is the minimum number of units that a business needs to have in stock to prevent stock outs and ensure order fulfillment. Once inventory levels reach the reorder point, this triggers the replenishment process to reorder that item. The ultimate goal of reorder point is to maintain an amount of inventory at a level that can always meet customer demand without having more than is realistically possible to move.

- The reorder point, also known as ROP, is the inventory level at which an order is triggered to replenish the inventory stock.

- Based upon either your sales history or a manually set reorder point.

- If you ever go below that mark, it’s time to set up new orders, or you may end up with empty shelves.

- You can run the reorder point formula manually, but it’s a lot faster to use automated software.

- This way, you’ll have sufficient stock to cover any increase in demand during the time it takes your supplier to produce and ship your order.

You can get stuck with dead stock and unsalable products while continuing to pay for the added cost of warehousing. Keep in mind that the calculations we’ve outlined here are more on the conservative end, aimed to prevent stockouts. You may find that the reorder point you’ve calculated using the aforementioned formulas is a bit too high for your taste.

In This Amazon Reorder Point Guide, Well Take A Look At:

As a rule of thumb, a reduction of 1% of the pinball loss will generate between 0.5% to 1% of safety stock reduction while preserving the same frequency of stock out. Not only can it help automate your reorder process, but it will ensure the numbers you base your strategy on are more accurate. Software also improves your efficiency and removes the chance for error, so your business can quickly adjust to changes in market conditions. You also have enough safety stock units – to cover problems with Supplier B or a sudden increase in demand. Individual products might sell faster during specific seasons, causing your sales velocity to spike temporarily. This formula alteration means that replenishment stock will be ordered sooner, which greatly reduces the risk that there will be a stockout condition.

In such a situation, a backorder made to a local supplier can be delivered before an older backorder made to an distant supplier. Is not suited for high service levels (in practice values above 90%). Indeed, the further away from the median (50%), the less accurate the normal approximation. To accurately calculate a product’s reorder point, it’s important to understand these factors and how they might impact your sales velocity. The reorder point is key for business owners to determine how much safety stock a business should keep on hand as a buffer for excess demand. Between calculating inventory for seasonal products to tracking cash limit for your reorders, managing stock and future order quantity can get tricky. Please note that the reorder point only indicates when to place a replenishment order; it does not calculate the amount of items that should be ordered .

The formula used to determine your inventory reorder point is relatively simple. It also plays a part in the broader scope of inventory management.

Applying reorder points to stock items is a relatively simple but effective method of ensuring stock is held at optimal levels. With often thousands of product lines and SKU’s and ever-shortening delivery times expected from customers ensuring that product lines remain in stock is critical to retaining customers.

For example, you can set inventory management software to automatically remind you when your inventory dips below a certain threshold. That way, you know exactly when you need to fill out and submit a purchase order without any wasted lead time. For instance, you may come in one Monday morning only to realize you’re out of a key product. Customer orders are pouring in and you remember your supplier has a lead time of one week.

- Nowhere does a third party have a more significant impact than within your supply chain.

- However, there are several things that retailers need to keep in mind while re-stocking their inventory and in this process, calculating the reorder point plays a very important role.

- If not, you could be missing out on a lot of revenue or spending more on inventory carrying cost than necessary.

- Just take the amount of items that are sold during a month and divide it by the number of days in this month.

- If you don’t you can look at inventory numbers and divide by the number of days between taking inventory.

- When an item absolutely needs to be in stock constantly the use of the backup ‘safety stock’ amount is reassuring and, when calculated correctly, an effective stock control measurement.

- Use POS data and empirical evidence to determine when to reevaluate your ROP.

Adding safety stock to this figure gives that extra measure of caution in case demand increases or something unexpected causes lead time to extend beyond the maximum. Supplier lead time, or the time it takes the supplier to manage an order and ship the goods.

For most companies, service levels float somewhere between 90 and 100 percent. For instance, if your service level is 92 percent, you’re saying you want to fulfill orders for this product at least 92 percent of the time. Consequently, businesses have embraced something called safety stock, also known as buffer stock. It’s an in-case-of-emergency stock businesses keep in case there’s an unexpected increase in demand or shortage in supply. Warehouses and distribution centers focused on growth, efficiency, and scalability use warehouse management systems and inventory management systems instead of Excel spreadsheets. These systems automate manual processes that are prone to human error or oversight. Ordering inventory is one example of an important process that can be automated with the right software.

Imagine a business (let’s call it J Timewear) in the United States sells watches manufactured in China. Assuming the supplier is always in stock and has a warehouse full of watches ready to ship at a moment’s notice, it’ll probably take the supplier a couple of days to pick and pack the watches. After that, the watches spend another five days in a truck to the Reorder Point port, and from there, it takes about 30 days for a ship to travel from China to the U.S.. Once the watches arrive, they spend another week in customs, and then another three days traveling to J Timewear’s warehouse. You can set up a low stock threshold set for each location and receive warnings when a product falls below this threshold at a specific location.

The desired level of service can be described as the amount of times you will be out of stock before the new shipment arrives. Setting reorder points is an important part of inventory management. There are several inventory management practices that are unavoidably labor intensive, like conducting annual counts or cycle counts, so it’s important to automate whenever possible. Calculating inventory reorder points, tracking inventory levels and placing orders can be effectively automated using warehouse and inventory management software. Reorder points usually incorporate safety stock, as shown in the standard formula just discussed. Even if they don’t do so explicitly, it’s good to build in some allowance to cover uncertainty and unexpected events.